Maximizing Efficiency: The Value of Genuine Komatsu Undercarriage Parts

Maximizing Efficiency: The Value of Genuine Komatsu Undercarriage Parts

Blog Article

Efficient Solutions: Undercarriage Components for Heavy Machinery

Quality undercarriage components play a considerable duty in guaranteeing the smooth procedure and longevity of hefty machinery. In this discussion, we will explore the importance of spending in top-notch undercarriage parts, usual wear challenges dealt with by heavy equipment operators, the advantages of timely substitutes, guidelines for selecting reliable distributors, and vital upkeep pointers to extend the life-span of undercarriage elements.

Importance of Top Quality Undercarriage Parts

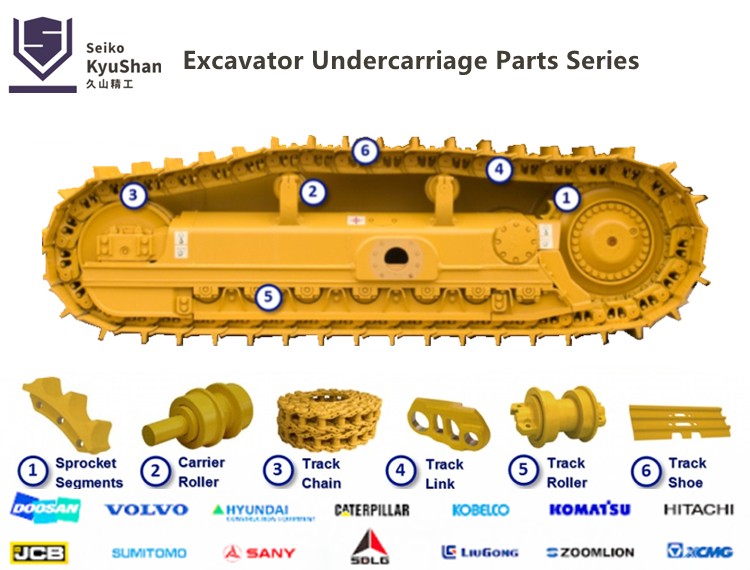

Quality undercarriage parts are important elements in ensuring the longevity and efficiency of heavy machinery. The undercarriage of tools such as excavators, bulldozers, and track loaders plays an essential duty in sustaining the equipment's weight, giving stability on various terrains, and taking in the impact of uneven surface areas. By spending in top notch undercarriage parts, operators can significantly expand the life-span of their equipment and lower the danger of unforeseen malfunctions.

One secret benefit of using quality undercarriage parts is the improvement of total equipment efficiency. Long lasting tracks, gears, idlers, and rollers minimize friction and ensure smoother movement, ultimately leading to raised performance and performance on task websites. Moreover, reliable undercarriage parts lessen downtime for repair and maintenance, permitting drivers to optimize their operational hours and project deadlines.

Usual Undercarriage Put On Concerns

Benefits of Timely Replacement

One trick benefit of prompt Get More Info undercarriage part substitute is increased machine uptime. By replacing used parts before they stop working, the danger of unexpected break downs is reduced, minimizing downtime for fixings and upkeep. This positive method not only keeps the heavy machinery functional however likewise prevents potential damages to various other elements that could result from a failing undercarriage.

Moreover, changing undercarriage components immediately can enhance general efficiency. A well-kept undercarriage guarantees optimal machine performance, enabling smoother procedure and higher effectiveness in completing tasks. This, consequently, causes enhanced work site productivity and expense savings by staying clear of hold-ups and interruptions triggered by underperforming equipment. Investing in timely undercarriage part substitute is a positive method that pays off in terms of boosted effectiveness and decreased operational costs.

Choosing the Right Undercarriage Vendor

Choosing the suitable undercarriage provider is a critical decision that considerably impacts the efficiency and maintenance of hefty machinery. When choosing a supplier for undercarriage components, several variables have to be taken into consideration to make sure optimal performance and cost-effectiveness. A vendor that uses a wide option of undercarriage components for different heavy equipment brands and designs can be helpful as it supplies a lot more choices to meet particular needs.

Balancing high quality, reliability, and cost-effectiveness is vital when picking the best undercarriage distributor for hefty equipment. By carefully assessing these aspects, you can select a vendor that satisfies your requirements and adds to the effective performance and upkeep of your hefty machinery.

Upkeep Tips for Extended Life-span

To make sure a prolonged lifespan for hefty machinery undercarriage parts, implementing a proactive upkeep regimen is essential. Frequently examining undercarriage elements such as track go to my blog chains, idlers, rollers, and sprockets for deterioration is vital. Any type of indications of damage or excessive wear need to be without delay resolved to avoid additional damage and possible failings. In addition, maintaining the undercarriage tidy from dust, debris, and destructive materials can considerably lengthen its life expectancy. Greasing relocating components according to supplier suggestions helps in reducing rubbing and stop premature wear. Keeping track of track stress and alignment is additionally important to prevent irregular wear on the undercarriage elements. Purchasing high quality undercarriage parts from trusted suppliers is just as vital for guaranteeing longevity. By adhering to these maintenance tips carefully, heavy equipment proprietors can enhance the performance and toughness of their undercarriage parts, eventually minimizing downtime and functional costs.

Conclusion

In final thought, quality undercarriage parts are crucial for the efficient operation of hefty equipment. Prompt substitute of used components can stop expensive downtime and maintain optimal efficiency. Picking a trusted distributor and complying with appropriate maintenance techniques are vital to making certain the expanded life expectancy of undercarriage elements. By attending to typical wear issues and purchasing top quality parts, heavy equipment operators can optimize performance and minimize maintenance prices.

Excessive wear and tear on undercarriage parts of heavy machinery can lead to significant functional challenges and increased upkeep costs. Normal i thought about this evaluations, correct maintenance, and prompt substitutes of worn undercarriage parts are important to reduce these common wear troubles and make sure the optimal performance of hefty machinery.

A distributor that uses a broad option of undercarriage components for various hefty machinery brand names and designs can be beneficial as it provides extra choices to fulfill details requirements.

By following these upkeep ideas carefully, hefty machinery owners can optimize the efficiency and durability of their undercarriage parts, ultimately decreasing downtime and functional expenses.

Report this page